Blog Standard

.jpeg)

Advanced Application of Differential Scanning Calorimetry (DSC) in the Lithium-ion Battery Manufacturing Industry

Lithium-ion (Li-ion) batteries represent the cornerstone of modern energy storage systems, spanning applications from consumer electronics to electric vehicles (EVs) and grid-scale storage. As their utilization continues to expand, there is a corresponding escalation in the demand for improved performance metrics, extended cycle life, and, critically, enhanced operational safety. Central to achieving these objectives is the in-depth understanding of the thermal behaviour of individual battery components. Differential Scanning Calorimetry (DSC) emerges as a pivotal technique in this context, offering quantitative and qualitative insights into the enthalpic and thermodynamic transitions occurring in battery materials under controlled heating or cooling conditions.

DSC measures the difference in heat flow between a sample and a reference as a function of time or temperature. It allows for the detection of a range of thermal events, including melting, crystallization, glass transitions, polymorphic transformations, decomposition reactions, and changes in heat capacity. These thermal fingerprints are invaluable in the assessment of battery component stability, compatibility, and phase behaviour, which directly influence battery safety and efficiency.

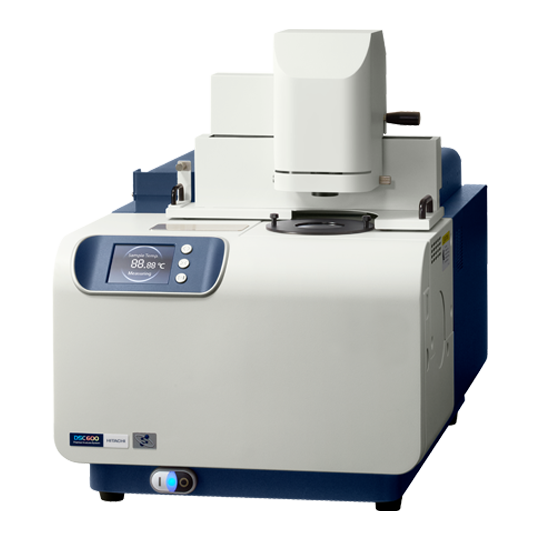

Hitachi NEXTA DSC200

2. Thermal Analysis of Electrode Materials

2.1 Cathode Materials

Layered transition metal oxides such as LiCoO₂, LiNiMnCoO₂ (NMC), and LiNiCoAlO₂ (NCA) are commonly employed as cathode materials due to their high energy density. However, at elevated temperatures, particularly beyond 200 °C, these materials can undergo exothermic decomposition associated with oxygen release from the crystal lattice. This oxygen can subsequently react with the electrolyte, leading to thermal runaway—a self-propagating failure mechanism.

DSC provides critical data such as the onset temperature of thermal decomposition (Tonset), the peak temperature of maximum heat release (Tmax), and the enthalpy of the exothermic event (ΔH). These parameters are essential for comparing the thermal stability of cathode chemistries. For example, NMC811, with a high Ni content, shows decomposition onset around 230 °C with a ΔH exceeding 1800 J/g, whereas NMC622 exhibits slightly higher thermal stability with lower associated heat release. Such data are indispensable in the design of safer battery packs, especially for EVs where passive propagation resistance is paramount.

2.2 Anode Materials

While graphite, the conventional anode material, exhibits relatively stable thermal behaviour, emerging alternatives such as silicon-based composites and lithium metal introduce significant thermal challenges. Lithiated graphite, for instance, can undergo exothermic reactions with electrolyte components upon heating, posing safety concerns. DSC enables the quantification of such reactions by capturing exothermic events either post-cycling or following controlled artificial lithiation in laboratory settings. The onset temperature, intensity, and enthalpy of these exothermic peaks provide valuable indicators of thermal reactivity and the potential for thermal propagation under extreme operating conditions. This makes DSC an essential diagnostic tool for assessing the safety margins of advanced anode systems.

3. Electrolyte and Solvent Thermal Profiling

The electrolyte system in Li-ion batteries typically comprises a lithium salt (e.g., LiPF₆) dissolved in a mixture of organic carbonates such as ethylene carbonate (EC), dimethyl carbonate (DMC), and diethyl carbonate (DEC). These solvents have low flash points and are susceptible to exothermic degradation at elevated temperatures, often catalyzed by trace moisture or impurities.

DSC enables the identification of critical parameters such as glass transition temperature (Tg), melting points (Tm), and decomposition onset temperatures. These transitions are significant for both lowtemperature performance and high-temperature safety. For instance, the Tg of EC:DMC mixtures can range from -60 °C to -40 °C depending on salt concentration and solvent ratio, affecting ionic conductivity at sub-zero temperatures. Moreover, the decomposition of LiPF₆-based electrolytes can occur around 150–180 °C, releasing HF and triggering secondary reactions. DSC profiles help formulate thermally robust electrolytes and screen additives (such as flame retardants or stabilizers) for enhanced safety.

4. Separator Melting and Shrinkage Behaviour

Polyolefin separators such as polyethylene (PE) and polypropylene (PP) are widely used due to their chemical inertness and mechanical strength. However, these materials melt at relatively low temperatures (~120–170 °C), compromising their dimensional stability and increasing the risk of internal short circuits under thermal stress. DSC is employed to precisely measure the melting points and thermal shrinkage behaviour of separator films.

For example, PP typically shows a sharp endothermic melting peak around 165 °C, whereas PE melts near 130 °C. Modified separators, such as those coated with ceramic layers (e.g., Al₂O₃ or SiO₂), exhibit delayed or suppressed melting signals, indicating improved thermal stability. DSC thus serves as a rapid screening tool for separator selection and development, especially when evaluating separators for use in high-temperature or high-power applications.

5. Evaluation of Binders and Electrode Formulation Components

Electrode binders such as polyvinylidene fluoride (PVDF), styrene-butadiene rubber (SBR), and carboxymethyl cellulose (CMC) contribute to electrode mechanical integrity and process ability. Their thermal behaviour during electrode drying and cell formation influences coating adhesion and interfacial stability. DSC allows the determination of the melting point, glass transition temperature, and thermal decomposition characteristics of these polymers.

For instance, PVDF shows a melting endotherm around 170–180 °C and degrades above 300 °C. Identifying these transitions ensures that the binder remains stable during processing and storage. Furthermore, additives like conductive carbon or functional polymers can be analyzed for thermal interactions with active materials or solvents. Any shift in thermal events indicates possible incompatibilities or synergistic interactions, which can be harnessed or mitigated accordingly.

6. Solid-State and Polymer Electrolyte Systems

With the rise of all-solid-state lithium batteries (ASSLBs), the characterization of inorganic and polymeric electrolytes has become increasingly important. DSC is indispensable for evaluating phase transitions such as crystallization, melting, or glass transition in these solid electrolytes. For example, polyethylene oxide (PEO)-based polymer electrolytes exhibit semi-crystalline behaviour with melting around 60 °C and a Tg near -60 °C. The degree of crystallinity and the thermal transitions influence ionic conductivity and mechanical properties.

Similarly, inorganic solid electrolytes like Li₇La₃Zr₂O₁₂ (LLZO) or NASICON-type materials may undergo phase transitions that affect their stability and performance. DSC can detect these subtle transitions, which are often correlated with ionic mobility and electrode–electrolyte interfacial resistance. Understanding these thermophysical properties enables the rational design of hybrid and composite electrolytes for next-generation solid-state cells.

7. Degradation Analysis

DSC also plays a crucial role in degradation analysis, especially when evaluating thermophysical changes in aged or cycled battery components. By comparing the thermal profiles of pristine versus aged materials, variations in crystallinity, heat flow, and decomposition behaviour can be identified. For instance, increased exothermicity in a cathode after extended cycling may indicate structural degradation or elevated surface reactivity. Likewise, the absence or shift of characteristic melting peaks in the electrolyte region may reflect salt decomposition or solvent loss.

In SEI (solid electrolyte interphase) characterization, DSC provides indirect evidence of SEI formation and evolution, especially when coupled with other techniques such as TGA or MS. Such thermal fingerprinting is useful in lifetime prediction, thermal tolerance assessment, and warranty analytics.

8. Thermal Safety Profiling

Battery safety evaluation under thermal, mechanical, or electrical stress conditions necessitates preliminary screening of material thermal sensitivity. DSC is routinely employed as a first-line technique prior to more advanced and resource-intensive methods such as Accelerating Rate Calorimetry (ARC). DSC offers critical early-stage data, including exothermic onset temperatures, total heat release, and thermal stability thresholds under both inert and oxidative environments.

Advanced DSC methods, including temperature modulated DSC (TM-DSC), enable deconvolution of overlapping thermal events, allowing for precise attribution of transitions. This is critical in constructing thermal propagation models for battery management systems (BMS), fire risk assessment, and compliance with regulatory standards (e.g., UN 38.3, IEC 62133, UL 1642).

9. Testimonials

DSC has emerged as a central tool for characterizing thermal events in lithium-ion battery materials. Zhang et al.1 explored mono- and bi-salt ether-based electrolytes for high-loading lithium-metal batteries and employed DSC to probe their thermal characteristics. The DSC analysis revealed Tg ranging from –61 °C to –53 °C, depending on the salt type and concentration, with no observable melting or crystallization peaks between –90 °C and 50 °C. This absence of phase transitions indicated a fully amorphous electrolyte system, critical for uniform ion conduction and thermal stability. Additionally, exothermic decomposition onsets were detected at 160 °C and 180 °C, correlating with enhanced thermal resilience of the electrolyte formulations. The DSC data provided valuable insight into the electrolyte's segmental dynamics and decomposition thresholds, essential for the design of safe, high-performance lithium-metal batteries.

Kimura et al.2 investigated a highly-concentrated poly(ethylene carbonate) (PEC)-based solid polymer electrolyte containing 80 wt% lithium bis(fluorosulfonyl)imide (LiFSI) supported by a 3D macroporous polyimide matrix. The Tg was observed at –47 °C, with no detectable crystallization or melting transitions in the –70 °C to 110 °C range. The preserved amorphous nature of the electrolyte, despite high salt loading, indicated effective suppression of chain ordering, which is critical for maintaining ionic conductivity and mechanical flexibility. The DSC utilized in this study provided critical insights into the thermal phase behaviour and segmental mobility of the polymer matrix, confirming the stability and amorphous character essential for room-temperature ion conduction. These results confirm that the pore-filled hybrid membrane retained its thermodynamic integrity and segmental mobility, enabling stable ion transport at room temperature in solid-state Li-ion cells.

Aldawsari et al.3 studied the thermal integrity of novel holey reduced graphene oxide/polystyrene (HRGO/PS) anode composites. The DSC thermogram revealed a broad endothermic baseline without distinct melting peaks up to 250 °C, indicating exceptional thermal stability and an absence of lowtemperature crystallization. An exothermic onset corresponding to polymer degradation was observed at ~305 °C, corroborating the material’s high-temperature resilience. The post-annealed HRGO/PS composite exhibited a 37% reduction in degradation enthalpy compared to pristine PS, evidencing enhanced thermal performance due to HRGO inclusion. These DSC insights substantiate the composite’s potential for high-temperature Li-ion battery applications.

Grewal et al.4 investigated the thermal transitions of bifunctional PEG-based cross-linked polymer electrolytes for all-solid-state Li-ion batteries. DSC analysis revealed distinct Tg ranging from –29.2 °C to –8.2 °C, depending on the [EO]/[Li⁺] ratio, with no observable melting or crystallization peaks up to 100 °C. The complete suppression of crystallinity confirmed the formation of an amorphous crosslinked network structure. An increase in Tg with rising Li⁺ concentration indicated restricted chain mobility due to transient coordination between lithium ions and PEG ether oxygens, enhancing thermal stability critical for electrolyte performance.

In their study, Xie et al.5 employed DSC to investigate the thermal behaviour of PVDF nanofiberreinforced solid polymer electrolytes (SPEs) for all-solid-state lithium-ion batteries. The DSC thermograms revealed Tm of the composite SPE increased from 149.6 °C (pristine) to 157.2 °C after incorporating crystalline PVDF nanofibers, indicating enhanced polymer crystallinity. Moreover, the exothermic decomposition onset temperature shifted from 215.3 °C to 231.8 °C, reflecting improved thermal stability and delayed degradation kinetics. The enthalpy of melting (ΔHm) also increased from 28.4 J/g to 35.7 J/g, suggesting better packing order and structural reinforcement within the polymer matrix. These thermal enhancements directly correlate with improved morphological and mechanical integrity of the SPE, emphasizing DSC's role as a precise diagnostic tool for screening thermally resilient battery electrolytes.

**All the thermal measurements were conducted using Hitachi High-Tech Differential Scanning Calorimeters.

10. Conclusion

DSC serves as a vital analytical technique within the lithium-ion battery manufacturing and research ecosystem. Its ability to precisely resolve thermal transitions in complex, multi-component systems enables in-depth evaluation of material compatibility, phase stability, and thermal decomposition thresholds. From optimizing separator compositions to enhance thermal tolerance, to screening cathode materials for resistance to exothermic runaway reactions, and evaluating the thermal stability of electrolyte formulations, DSC provides critical thermodynamic data essential for the rational design of safe and high-performance battery systems. As the field advances toward solid-state configurations and next-generation chemistries, the strategic importance of DSC continues to expand—cementing its role as a cornerstone of advanced materials characterization in battery innovation.

DSC – A standard thermal profiling Tool to build safer and performance-oriented powerful next-gen batteries

References:

1. J. Lee, J. Park, J.W. Park, et al., Supramolecular gels with high strength by tuning of calix[4]arene-derived networks, Nat. Commun. 6 (2015) 6650. https://doi.org/10.1038/ncomms7650.

2. . K. Kimura, M. Yajima, Y. Tominaga, A highly-concentrated poly(ethylene carbonate)based electrolyte for all-solid-state Li battery working at room temperature, Electrochem. Commun. 63 (2016) 46–49. https://doi.org/10.1016/j.elecom.2016.02.002.

3. Y. Aldawsari, Y. Mussa, F. Ahmed, M. Arsalan, E. Alsharaeh, Novel synthesis of holey reduced graphene oxide/polystyrene nanocomposites by microwave irradiation as anodes for high-temperature lithium-ion batteries, Mater. Today Proc. 12(14) (2019) 2248. https://doi.org/10.3390/ma12142248.

4.M.S. Grewal, M. Tanaka, H. Kawakami, Bifunctional PEG-based cross-linked network polymers as electrolytes for all-solid-state lithium-ion batteries, Polym. Int. (2024). https://doi.org/10.1002/pi.5750.

5. L. Xie, Q. Wu, H. Liu, F. He, X. Huang, J. Peng, Y. Zhang, G. He, Enhancing lithium ion conductivity and all-solid-state secondary battery performance via crystalline PVDF nanofibers, Solid State Ionics 370 (2021) 115095. https://doi.org/10.1016/j.ssi.2021.115095.