Blog Standard

Advancing Edible Oil Quality Control with FT-NIR Spectroscopy

In the food industry, ensuring the quality and safety of edible oils is critical for meeting consumer expectations and regulatory standards. From seed oil to finished products like sunflower oil, canola oil, and soybean oil, producers face challenges in maintaining consistent quality. Traditional analytical methods are often slow and involve hazardous chemicals. Bruker Optics revolutionizes edible oil quality testing with FT-NIR spectroscopy, a non-destructive testing method that delivers rapid, accurate results. This blog explores how FT-NIR analyzers enhance quality control across the entire edible oil production chain, from seed reception to by-product analysis, ensuring efficiency, safety, and compliance.

This experiment aims to perform the Kolbe-Schmitt reaction on resorcinol (1,3-dihydroxybenzene) to yield β-resorcylic acid (2,4-hydroxybenzoic acid) through carboxylation in an aqueous sodium bicarbonate solution. The product is subsequently analyzed using benchtop NMR spectroscopy, including HSQC NMR experiments, to elucidate molecular structure and couplings in aromatic compounds. This experiment provides students with hands-on experience in spectral analysis and dynamic insights into the behavior of organic compounds through spectroscopy.

The Power of FT-NIR Spectroscopy in Edible Oil Analysis

Near-infrared spectroscopy is a well-established technique in agriculture, and its adoption in the food industry is growing. FT-NIR spectroscopy, pioneered by Bruker Optics, offers a non-destructive testing solution for analyzing both liquid and solid samples. Unlike traditional wet-chemical or chromatographic methods, which are time-consuming and require hazardous solvents, FT-NIR analyzers provide a safer, faster alternative. These systems deliver precise results without sample preparation, reducing costs and environmental impact, making them ideal for the edible oil industry.

Quality Control Across the Production Chain

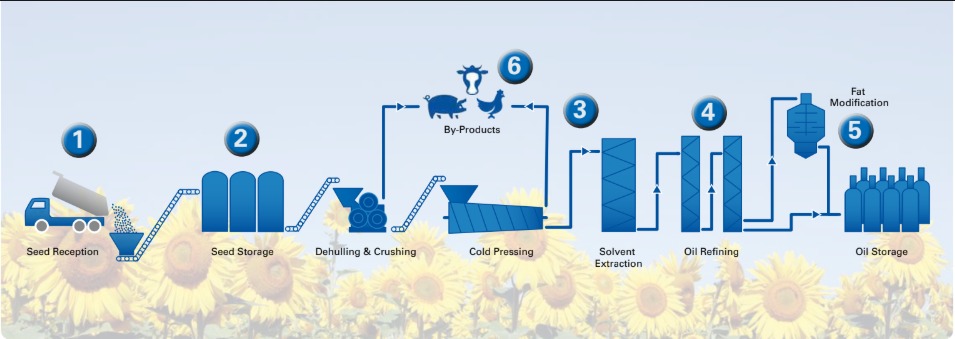

FT-NIR spectroscopy supports quality control at every stage of edible oil production, from seed reception to by-product utilization. Bruker Optics’ solutions ensure optimal quality and process efficiency

Figure 1. Production Chain

Seed Reception

Analyzing incoming oilseeds, such as sunflower seed oil, rapeseed, canola oil, soybeans, and sesame seed, at the reception bay is crucial for quality control and fair pricing. Traditional methods often involve sending samples to external laboratories, causing delays. FT-NIR analyzers enable rapid, on-site analysis, allowing tight quality control before seeds are discharged, ensuring only high-quality seeds proceed to processing.

Storage

Proper storage of oilseeds is essential to prevent bacterial, fungal, or mold growth, which can render seed oil unfit for consumption and lead to profit losses. FT-NIR spectroscopy monitors moisture content and storage conditions, ensuring optimal seed quality for processing. Regular analysis also supports drying processes, maintaining seed integrity over extended storage periods.

Oil Extraction

Cleaning, drying, dehulling, and flaking maximize oil yield from seeds. FT-NIR spectroscopy monitors moisture and oil levels in seeds and expeller cakes, providing quick insights into extraction efficiency. It also analyzes crude oil for parameters like free fatty acids, phospholipids, and waxes, optimizing conditions for the subsequent refining process.

Oil Refining

Refining removes undesirable substances like free fatty acids and colors but may eliminate valuable components like antioxidants. FT-NIR analyzers enable close monitoring of refining processes and final product testing, both in the lab and through real-time, online process analytical technology. This eliminates delays and costly rework, ensuring high-quality oils.

Fat Modification

Natural oils often require modification through fractionation, interesterification, or hydrogenation to meet food industry demands. FT-NIR spectroscopy monitors physical and chemical properties, including fatty acid profile, free fatty acids, trans fatty acids, iodine value, and solid fat content (SFC), ensuring the modified oils meet nutritional and functional requirements.

By-Products

By-products like hulls and expeller cakes are valuable for industries such as animal feed. FT-NIR analyzers assess parameters like moisture, oil, protein, fiber, and ash content in under a minute, helping determine market value and ensuring quality for secondary applications.

Quality Control of Finished Edible Oils

Edible oils, including sunflower oil, canola oil, soybean oil, corn oil, fish oil, tallow, and lard, require rigorous quality assessment. FT-NIR analyzers measure critical parameters such as free fatty acids, trans fatty acids, iodine value, peroxide value, anisidine value, fatty acid profile, triglyceride profile, SEC screening, saturation, and color. These measurements align with standards set by the American Oil Chemists’ Society (AOCS) and the German Society for Fat Science, replacing slow traditional methods with rapid, reliable results.

Olive Oil Authentication: Ensuring Liquid Gold

Extra virgin olive oil, produced through cold-pressing without chemicals, is prone to adulteration due to its premium value. FT-NIR spectroscopy provides a robust solution for olive oil authentication, monitoring the production process and detecting low-quality or adulterated oils, ensuring consumer trust and brand integrity.

Optimizing Best Frying Oil Quality

The quality of best frying oil significantly affects the taste, color, and safety of fried foods. FT-NIR spectroscopy monitors frying oil degradation, analyzing parameters like free fatty acids, total polar compounds, polymerized triglycerides, and anisidine value. Recognized by the German Society for Fat Science in their 2013 Standard Method, FT-NIR analyzers deliver accurate, rapid results, enabling consistent quality in fast-food and large-scale frying operations.

Process Analytical Technology for Real-Time Control

FT-NIR spectroscopy is integral to process analytical technology (PAT) in food processing technology. The Bruker Optics MATRIX-F spectrometer supports online process control for solid and liquid samples, using contact and non-contact sensors, including fiber optic probes that withstand temperatures up to 260°C. This enables continuous monitoring in industrial deep-fat frying, ensuring optimal oil quality, reducing waste, and enhancing economic efficiency.

Bruker MATRIX-F II FT-NIR Spectrometer

State-of-the-Art Technology for Reliable Results

Bruker Optics’ FT-NIR analyzers feature the RockSolid interferometer with cube corner mirrors, resistant to vibration and thermal effects. This ensures stability and reliability in harsh factory environments. The pre-aligned, user-replaceable light source minimizes downtime, and precise wavelength accuracy supports calibration transfer, making these analyzers ideal for both lab and production settings.

Advanced Software Solutions

The OPUS software suite enhances FT-NIR analyzers with tools for calibration development, raw material identification, and conformity testing. The Multi Evaluation (ME) function automates hierarchical analyses, combining identification, quantification, and conformity tests. OPUS/LAB offers an intuitive interface for routine operators, while OPUS/PROCESS supports automated process control with integration options like Profibus DP, Modbus, and OPC. The software ensures data security with GMP/GLP compliance, 21 CFR Part 11 conformity, and permanent online diagnostics.

Conclusion

FT-NIR spectroscopy from Bruker Optics transforms edible oil quality testing by providing a rapid, non-destructive testing solution across the production chain—from sunflower seed oil reception to olive oil authentication and by-product analysis. By integrating process analytical technology, producers achieve real-time control, reduce costs, and meet stringent standards. With robust technology, intuitive software, and comprehensive support, FT-NIR analyzers empower the edible oil industry to deliver high-quality products consistently. Embrace the future of food processing technology with Bruker Optics to elevate quality control to new heights.

Inkarp Instruments is a premier distributor and dependable service partner for Bruker products in India. Committed to innovation and excellence, Inkarp supplies advanced scientific instruments along with expert support, enabling researchers across the country to drive groundbreaking discoveries.

References: Bruker