Blog Standard

Advancing Polymer Synthesis for a Sustainable Future

prompting innovative solutions in polymer synthesis and recycling. Researchers are now focusing on creating polymers that can be chemically recycled, addressing limitations in traditional plastic recycling methods, such as the inability to remove colorants. At Cardiff University, groundbreaking work using the Radleys Reactor-Ready system has led to the development of single-component, colored polymers that can be depolymerized and remade into colorless materials, offering a promising path toward sustainability. This article explores how these advancements in chemical synthesis and reactor technology are revolutionizing the plastics recycling industry and paving the way for materials science innovations.

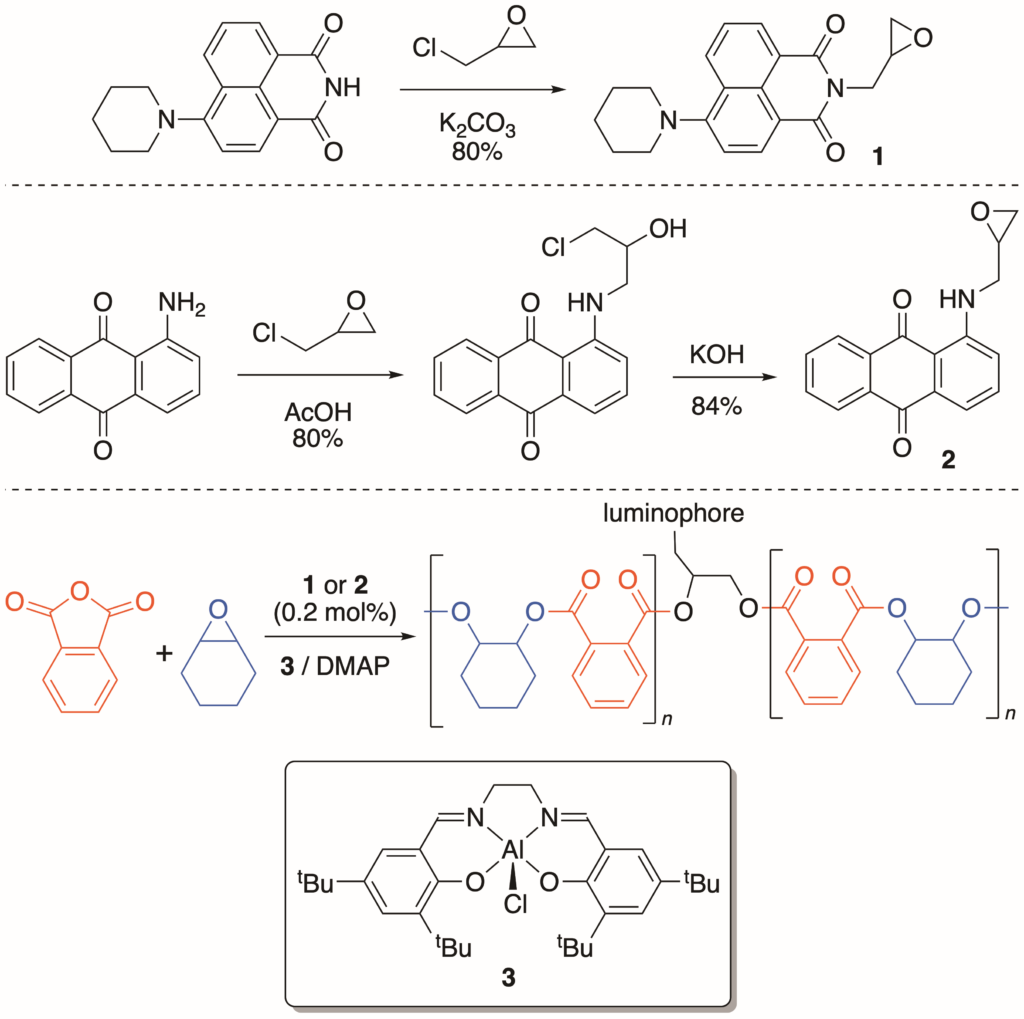

Developing Colored Polymers with Chromophore Integration

In the realm of organic chemistry, researchers at Cardiff University have pioneered a method to synthesize glowing polymers using epoxide-anhydride ring-opening copolymerization (ROCOP). By incorporating chromophore-containing monomers, they create highly colored polymers with covalent bonding of dyes, requiring only minimal dopant levels. This approach ensures that the polymers retain the properties of the base material while exhibiting vibrant coloration and luminescence, critical for applications in fluorescent polymer research and advanced materials development. The result is a versatile polymer with tailored optical properties, suitable for various industrial polymer applications.

Scaling Synthesis with Reactor-Ready Technology

The synthesis of these innovative polymers was conducted on a laboratory scale using a Radleys Reactor-Ready 2-litre Jacketed Lab Reactor, equipped with a Hei-TORQUE stirrer and a Huber Ministat for precise temperature control. This lab reactor enabled the production of 280–320 grams of material in a single reaction, demonstrating its capability for polymer scale synthesis. The use of an external PT1000 temperature probe with the Huber Ministat allowed researchers to monitor and control reaction temperatures effectively, mitigating the risks of exothermic reactions common in large-scale epoxide homopolymerizations. This setup ensures safety and consistency, making it ideal for scaling up chemical reactions in research settings.

Radleys Reactor-Ready™Flex Lab Reactor

Revolutionizing Plastic Recycling

A key breakthrough in this research is the ability to chemically recycle colored polymers back to their parent acid or alcohol, removing the chromophore to produce colorless, pure polymers. Unlike traditional plastic recycling, which struggles with persistent colorants, this method allows for the complete regeneration of base monomers, which can then be repolymerized into high-quality, color-free materials. This innovation addresses a critical challenge in the plastics recycling industry, offering a sustainable solution that supports a circular economy. The strategy’s f lexibility also allows for the integration of various dopants, enabling the creation of polymers with customized properties for diverse applications.

Impact on Materials Science and Industry

The advancements achieved through this research have far-reaching implications for materials science innovations and industrial polymer applications. By enabling the production of recyclable, functional polymers with tailored properties, this approach supports the development of sustainable materials for industries ranging from packaging to electronics. The ability to scale up polymer synthesis using advanced reactor systems like the Radleys Reactor-Ready ensures that these innovations can transition from the lab to industrial settings, driving progress toward a more sustainable future.

Conclusion: A Path to Sustainable Polymer Production

The work at Cardiff University highlights the transformative potential of chemical synthesis in addressing environmental challenges. By leveraging the Radleys Reactor-Ready system for polymer scale production and developing recyclable, glowing polymers, researchers are redefining the possibilities in the plastics recycling industry. These materials science innovations not only solve critical recycling challenges but also open new avenues for creating advanced, sustainable materials. As this technology scales, it promises to reshape how we produce, use, and recycle polymers, fostering a more sustainable and innovative future.

Inkarp Instruments is a trusted distributor and service provider of Radleys products in India, delivering advanced scientific solutions tailored to the needs of contemporary research. Committed to excellence, we empower scientists across the country with innovative technology and expert support to advance discovery and innovation.

References: Radleys